Dust collection is one of the most overlooked—but most important—parts of a safe and efficient woodshop. While sawdust might seem like a harmless byproduct of woodworking, the reality is that fine wood dust can pose serious health risks, damage tools, and create unnecessary cleanup work if not properly managed.

In this guide, we’ll break down why dust collection matters, the different dust collection options available, and how to set up an effective system for your woodshop, whether you’re working in a garage shop or a dedicated workspace.

Why Dust Collection Is Critical in a Woodshop

1. Health and Safety

Fine wood dust is a known respiratory hazard. Prolonged exposure can lead to:

- Allergies and asthma

- Chronic sinus issues

- Long-term lung damage

Certain woods, such as walnut, oak, and exotic species, are especially irritating and can be toxic over time. Effective dust collection helps remove airborne particles before they’re inhaled.

Another type of wood product I use in my workshop is MDF. Medium-Density Fiberboard (MDF) is an engineered wood product made from fine wood fibers combined with resin and wax, then compressed under high heat and pressure. The result is a dense, smooth, and uniform panel with no visible grain.

I typically use MDF a lot for projects that I want to paint because it leaves a flawless finish. MDF is poplar for cabinets, trim, furniture backs and so much more. DUST COLLECTION and a good mask is a MUST for MDF because it is more toxic than wood.

2. Cleaner, More Efficient Workflow

A shop filled with dust slows you down. Good dust collection:

- Keeps work surfaces visible

- Reduces cleanup time

- Improves accuracy when cutting and sanding

3. Tool Longevity

Dust buildup inside tools and motors can shorten their lifespan. Proper dust collection reduces wear on bearings, motors, and moving parts.

Types of Dust Collection Systems

Shop Vacs

Shop vacuums are a common starting point for small shops.

Best for:

- Sanders

- Routers

- Miter saws

- Jobsite tools

Pros:

- Affordable

- Compact

- Easy to move

Cons:

- Limited airflow

- Not ideal for large stationary machines

Tip: Use a HEPA filter and a cyclone separator to dramatically improve performance.

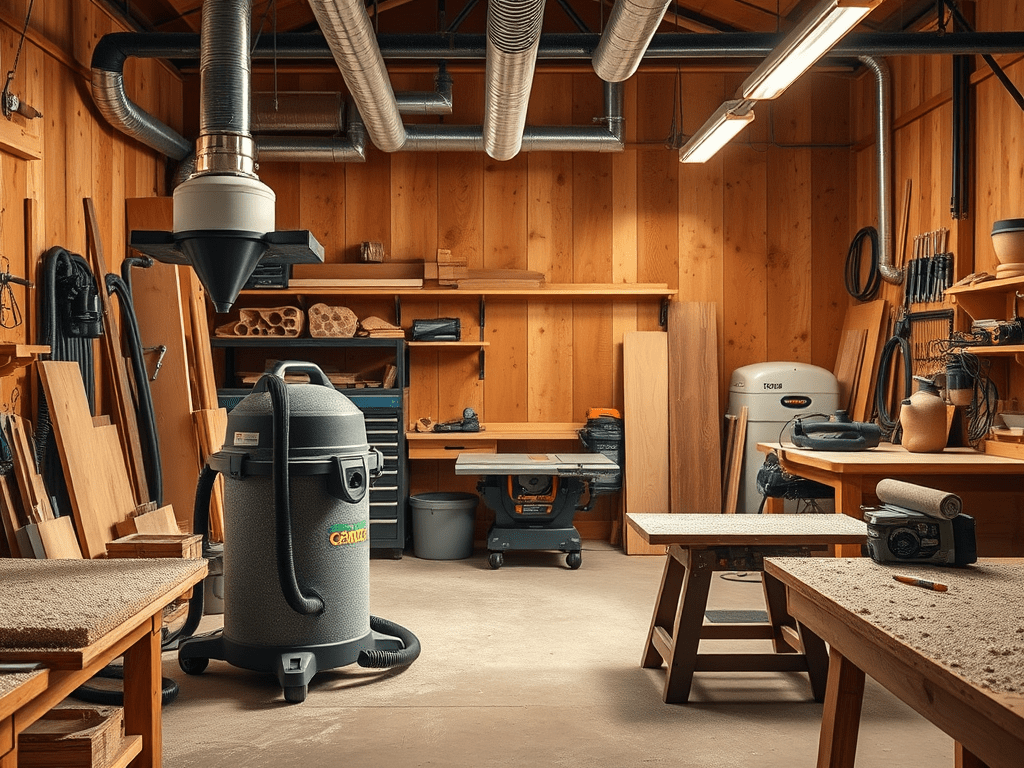

Since I do art work I have found two large shop vacs with cyclone separators work very well in my shop even though I use big items like a table saw, bandsaw, jointer and planner. I use a 16 gallon Stealthsonic vac by Dewalt with a large metal drum cyclone dust separator. I have magnetic connectors on my big tools (table saw, planner, jointer, and bandsaw). Then I have a separate 12 gallon stealthsonic vac with a second slightly smaller dust cyclone for my smaller tools (scrollsaw, sanders, and for clean up). Since I don’t make as much dust as a someone who make furniture it works well in my shop.

I do have a hanging overhead Air Filtration unit to capture some of the airborne dust that floats in the air.

Once you figure out what your shop needs you can decide which type of dust collectors you might need depending on the amount of dust you make.

Single-Stage Dust Collectors

These are larger units typically rated between 1–2 HP.

Best for:

- Table saws

- Jointers

- Planers

- Bandsaws

Pros:

- High airflow (CFM)

- Handles larger chips and dust

Cons:

- Takes up more space

- Usually requires ducting

Two-Stage & Cyclone Systems

Cyclone systems separate heavy debris before it reaches the filter.

Best for:

- Dedicated or professional shops

- Multi-machine setups

Pros:

- Excellent filtration

- Less filter clogging

- Handles fine dust well

Cons:

- Higher cost

- Larger footprint

Key Components of an Effective Dust Collection Setup

Proper Ducting

- Use smooth-wall piping (metal or PVC)

- Minimize sharp turns

- Keep runs as short as possible

Blast Gates

Install blast gates at each machine to:

- Direct airflow where it’s needed

- Improve suction

- Reduce system strain

Filters Matter

A dust collector is only as good as its filter.

- Look for 1-micron or better filtration

- HEPA filters are ideal for fine dust control

Dust Collection vs. Air Filtration

Dust collection captures debris at the source.

Air filtration units clean what’s already in the air.

For best results:

- Use both

- Dust collection at machines

- Ceiling-mounted air cleaner for lingering dust

Common Dust Collection Mistakes to Avoid

- Using undersized hoses

- Ignoring fine dust filtration

- Running multiple machines without enough CFM

- Relying on a broom instead of extraction

Choosing the Right Dust Collection System for Your Shop

Ask yourself:

- How big is my shop?

- What tools do I use most?

- Do I work with hardwoods or MDF often?

- How much space and budget do I have?

There’s no one-size-fits-all solution—but even a basic dust collection setup is far better than none.

Final Thoughts

Dust collection isn’t just about cleanliness—it’s about protecting your health, your tools, and the quality of your work. Investing time and money into a proper dust collection system will pay off every time you step into the shop.

Whether you’re a weekend woodworker or running a small woodworking business, improving your dust collection is one of the smartest upgrades you can make.

Until Next time.

Elizabeth

Leave a comment